Nanshan Fashion, Private Placement Approved!

Release time:2025-02-10

Nanshan Fashion(300918)achieves a new milestone in stock issuance to specific entities!

On the evening of February 5,Nanshan Fashion announced that its application for the private placement of shares to specific entities had been approved for registration by the China Securities Regulatory Commission.

Nanshan Fashion's refinancing process has passed through various stages,including approval by the company's board of directors,review by the shareholders'meeting,and examination by the Shenzhen Stock Exchange,before ultimately receiving the approval for registration from the China Securities Regulatory Commission.

Upon the successful completion of the issuance,the influx of raised funds will significantly increase Nanshan Fashion's total assets,net assets,and cash flow from financing activities.This will enhance the company's overall financial strength,optimize its equity structure,and improve its competitiveness.

Strategically focusing on Nylon 66,with the project already entering trial production ahead of schedule

In recent years,Nanshan Fashion has continued to strengthen its focus on fine woolen spinning and apparel,leveraging"high-tech and high-value-added product transformation"as a key strategy.The company has prioritized the development of new synthetic fiber materials,with a particular emphasis on the application of ultrahigh molecular weight polyethylene fibers in specialized protection,civilian,and marine sectors.Additionally,Nanshan Fashion has been advancing its nylon filament project,further enriching its textile fiber portfolio,and establishing a fully integrated industrial chain driven by"traditional woolen apparel+new material fibers."

Nanshan Fashion Functional Fabrics

Nanshan Fashion Custom Apparel

Nanshan Fashion Ultrahigh Molecular Weight Polyethylene Workshop

Nanshan Fashion Nylon New Materials Workshop

It is understood that the net fundraising amount from Nanshan Fashion's private placement,after deducting issuance costs,will be fully allocated to the high-performance differentiated nylon filament project.The project commenced construction in August 2023 and entered trial production ahead of schedule by the end of November last year,shortening the planned construction period by nearly six months.Once fully operational,it will increase nylon fiber production capacity by 80,000 tons,including 36,000 tons of Nylon 66 products,which is the key focus of Nanshan Fashion's project strategy.

Currently,driven by healthy lifestyles such as outdoor sports,yoga,and fitness,and supported by the domestication of raw materials that have reduced product prices,the market demand for Nylon 66 products has further expanded.

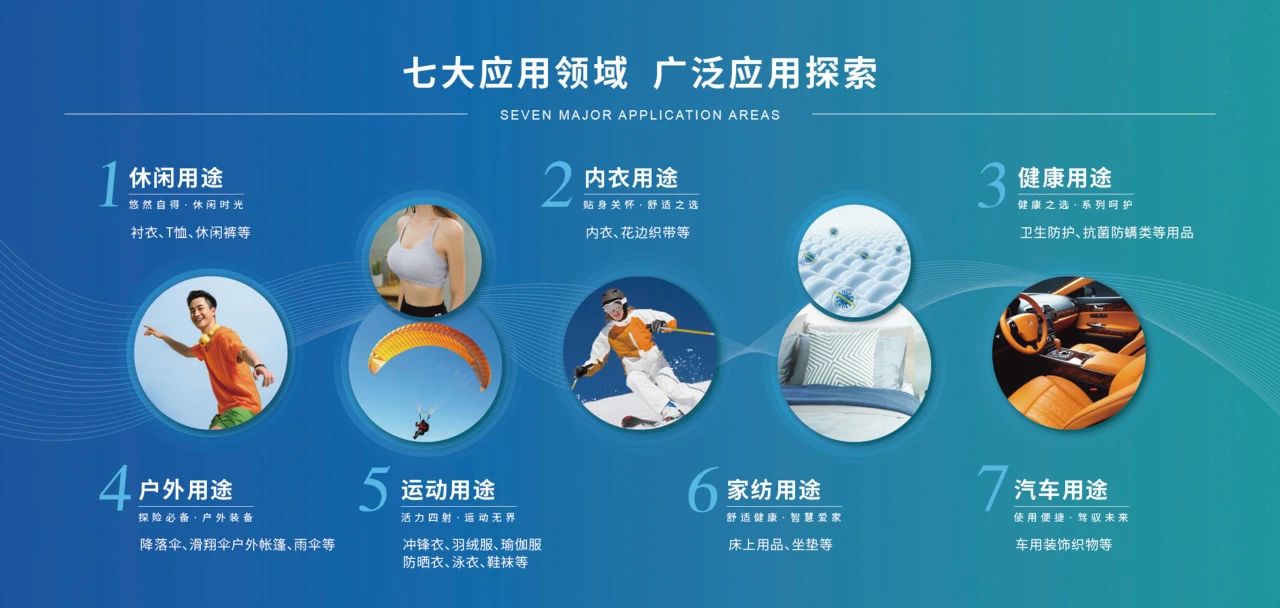

In addition,Nylon 66,a fiber that is"as fine as spider silk,as strong as steel wire,and as beautiful as silk,"is not only used in outdoor and sports apparel but also widely applied in leisurewear,lingerie,home textiles,healthcare,automotive,and military equipment,among other industries.

According to Euromonitor's data,the global outdoor and sports apparel market grew from$176.702 billion in 2020 to$230.864 billion in 2023,with a five-year compound annual growth rate(CAGR)of 5.5%.In comparison,the overall global apparel market had a five-year CAGR of 3.9%.In the domestic market,the market size for Nylon 66 apparel also showed rapid growth,rising from¥132.384 billion in 2020 to¥161.743 billion in 2023,with a CAGR of 4.1%.

Leveraging industry synergies to set industry standards

Currently,Nanshan Fashion has become one of the few A-share listed companies capable of producing Nylon 66 filaments for civilian use.

According to the company,Nanshan Fashion's nylon project has at least three major advantages:First,product variety—The company focuses on differentiated,functional Nylon 6 and Nylon 66,which have strong market competitiveness due to their differentiation.Second,quality and cost—Some of the nylon production lines will use ring-blowing production technology,which allows for strict control of workshop temperature and humidity to improve product quality stability.At the same time,fully automated production lines help reduce production costs.Third,and most importantly,industry chain advantage.

Additionally,Nanshan Fashion has stated that it has already signed preliminary agreements for the sale of nylon filaments with certain customers prior to the official start of production.The benefits of industry synergies have allowed Nanshan Fashion to offer nylon filament products at lower costs,improved quality,and more competitive prices,enabling the company to rapidly capture market share.

Nanshan Fashion's expansion in the new materials sector continues to achieve significant milestones.The company now holds a production capacity of 3,600 tons of ultrahigh molecular weight polyethylene fibers,placing it in the industry's top tier.The products are positioned as high-end,with quality and specifications aligned with global industry leaders.The successful implementation of the nylon project not only strengthens the core business but also furthers the company's industrial upgrade.

Latest information